The system of prototyping is presented as a gathering of procedures, which uses progressed types of gear and 3D PC supported plan or CAD information to deliver an example scale for a physical item or get together in a most ideal manner. It comprises of a CAD cycle, which begins with formation of mathematical information either utilizing 2D cutting with a scanner gadget or 3D strong with a CAD workstation. The client ought to speak to legitimate mathematical information model of this prototyping system. Sound system lithography planned with hello their tech 3D frameworks is considered as the essential rapid prototyping measure. What is more, you can likewise perceive the rapid prototyping technique as PC robotized fabricating, layered assembling or freestyle producing. Fundamentally, a vehicle is clearly utilized by this cycle for perception of the scale model.

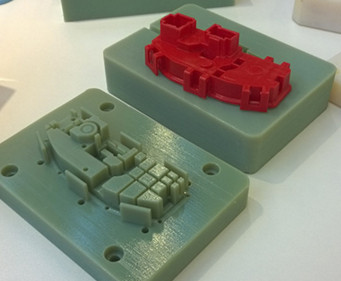

For tooling reason, this cycle is additionally relevant to configuration tests of male models like venture projects and elastic molds made with silicon. Quality rapid tooling company discovers applications in testing the plans of any item and framework by making test first. Also, exceptionally tangled shapes are handled by this strategy. This strategy is known as first example before delivering the molds in China. This gives an office to the originator to create an example as per the guidelines of mechanical drawings and outsides for the check reason. It confirms the assessment of appearance and mechanical plan soundness of a specific item. This cycle is need as the primary stage subsequent to finishing the R and D and configuration cycle to check the possibility of an item. So as to discover imperfections and deficiency in an item plan, this technique is accessible as best, proficient and direct way. For the most part, it isn’t fundamental that an item is planned consummately for each time, even direct assembling an end result may cause for an extraordinary wastage of time, cash and labor.

Along these lines, rapid prototyping strategy gives a low volume item test for making enhancements and for enormous creation. The cycle can be arranged as added substance fabricating, CNC machining, sheet metal, CNC turning, CNC processing and trim. It decreases the dangers identified with form making and abbreviate the time span for item accessibility. Plastic materials like PU, PC, PP, POM, PE, PA12, ABS, PA+GF, PMMA, PA6/66 or metal combinations like magnesium amalgam, silver, aluminum, copper, carbon steel, SST steel and zinc composite are utilized in this technique. It is an ideal visual and substantial approach to portray the possibility of a creator in a physical structure. Besides, this strategy likewise evades the instance of the genuine plan of an item not look in a way that is better than its applied plan. The imperfection hazards identified with an item configuration additionally lessen by utilizing this cycle in a solid manner. Moreover, this is utilized by various businesses to make test for their items.