3D update pads innovation, which is the most settled Additive Manufacturing progresses, is getting energy in the prototyping scene by virtue of its new materials showing thermoplastic-like displays. This additional substance creation measure considers eccentric part designs just as passes on valuable models, which works with thought part testing. Arrangement assembles right now spare a colossal proportion of time when they test an arrangement thought. In the generally late past 3D memo pad SL saps were exorbitantly delicate to consider for instance evaluating the impact hindrance of a model. By virtue of the various advances of Additive Manufacturing advancements, and appreciation to the essential reduction of a chance to-exhibit they bring to part fashioners, the furthermore called Rapid Prototyping industry is growing fast and arrived at US$ 1.1 billion out of 2009.

With a yearly improvement of more than 20% and benefitting by additional specific advances on materials, the Rapid Prototyping and Rapid Manufacturing advances will show fundamentally more in the next many years. Another flood of chances has quite recently spread into this rapidly creating industry. The production of short runs AM progresses when in doubt, and 3D memo pad explicitly, are by and by more than ever used to convey a set number of parts, regardless, when it oversees for instance complex arrangement of additional parts. The mixture trim of plastic parts is not kidding when only a few of parts are needed considering the way that the steel structure cannot be amortized. This is one motivation behind why the AM developments including 3D memo pad progresses are fitting for the aeronautical business. For a comparative clarification the clinical part is moreover extensively using 3D update cushion and the other Rapid Prototyping and Rapid Manufacturing developments. Since every tolerant is stand-out, dental supplements and other versatile speakers will reliably be made on solicitation, and drawings will change beginning with one patient then onto the following.

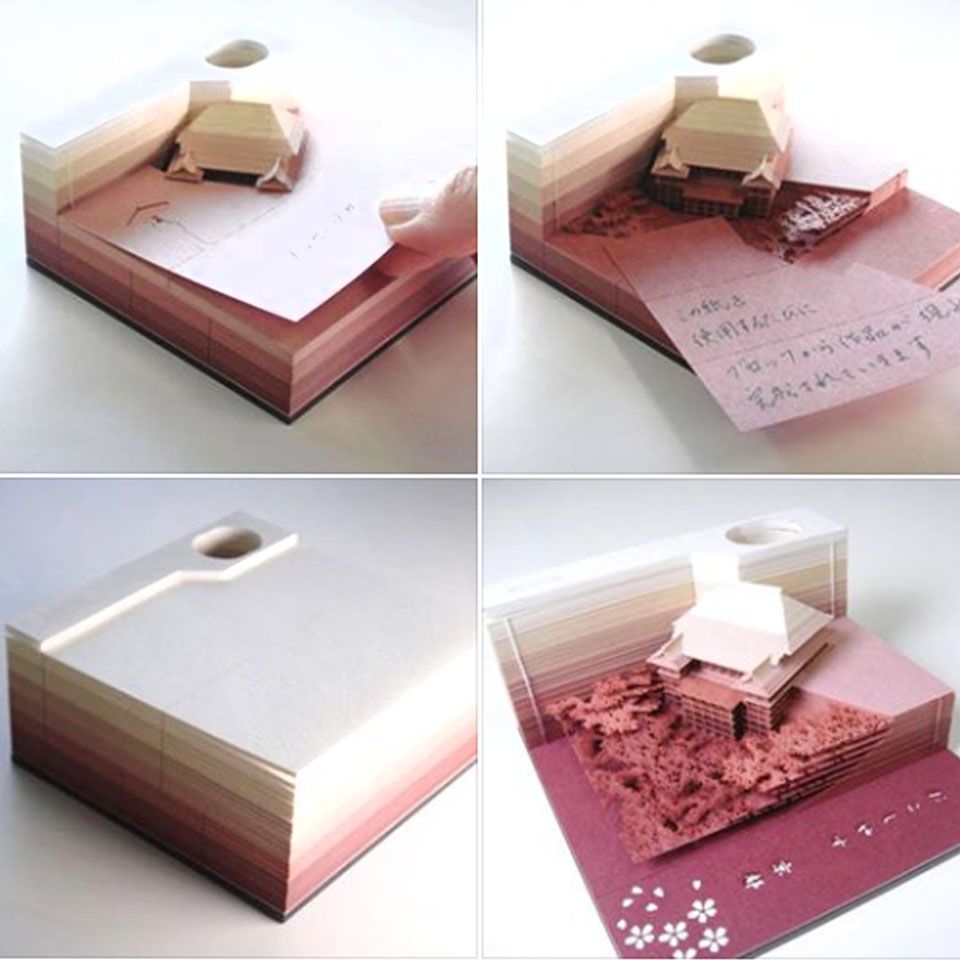

Regardless of the way that the SL development is making progress in managing short runs and making confined proportion of additional parts, it is still essentially used in the prototyping scene. Following T. Wohler’s, a renowned and eminent expert in the 3d printing developments, there are by and large 70% of parts using AM progresses being sold as models or exceptional models1 and look at Omoshiroi Block. Notwithstanding the creating excitement towards the gathering of redid parts there were furthermore some key advances made these earlier years on materials to improve the displays of models. It is by and by easy to get utilitarian models. Pitch creators made excellent gums for AM developments to make them nearer to the successive creation tars – whether or not these AM saps would not ever be the particular adjusted of mixture forming assessments experts at present talk of for instance ABS-like properties materials.